Why Welding Cobots Matter — And How They Benefit Your Business

- Faythe Hawley

- May 5, 2025

- 2 min read

In the world of metal fabrication, quality, speed, and consistency matter. If you're a business that relies on fabricated metal parts—whether for equipment, structures, enclosures, or components—there’s a good chance your suppliers are using (or should be using) welding cobots.

But what does that mean for you?

Let’s break down why working with a fabrication company that uses cobot welding can give you a serious edge.

What is a Welding Cobot?

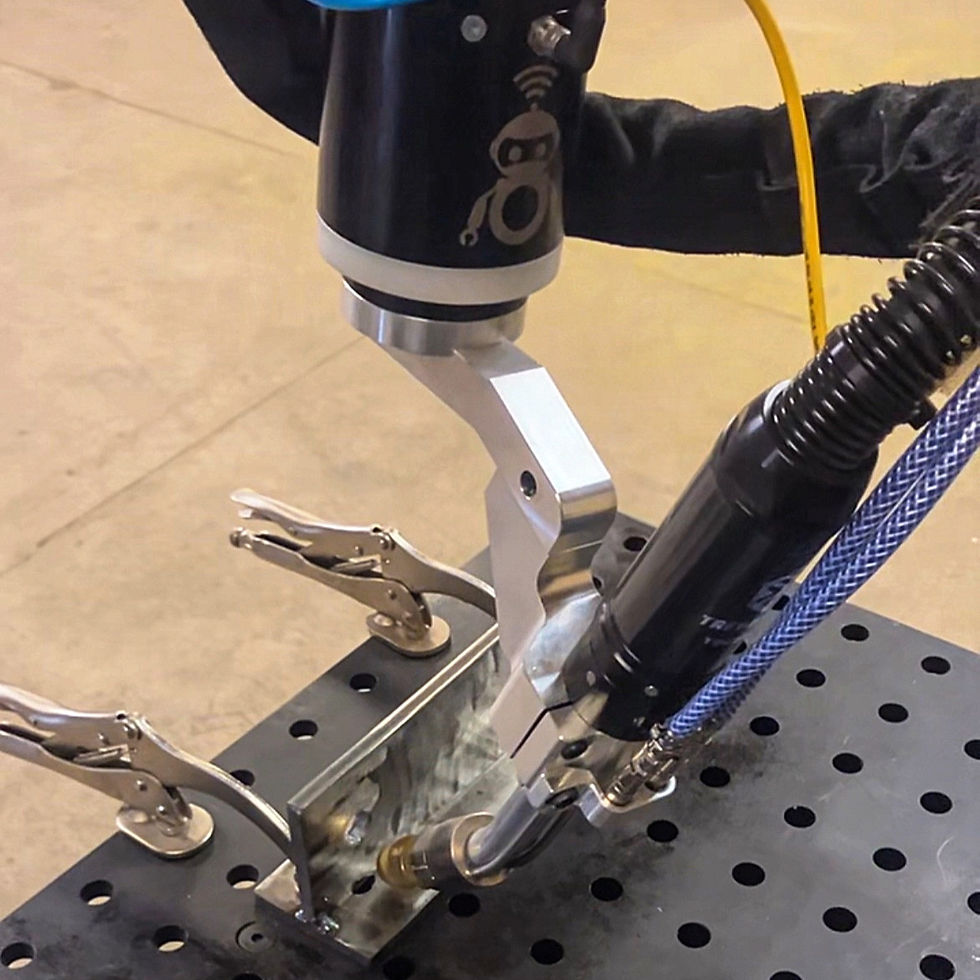

A welding cobot (short for "collaborative robot") is a robotic welding system designed to work safely alongside humans. Unlike traditional robots, cobots are flexible, cost-effective, and ideal for automating repetitive welds—without the need for big, expensive production lines.

They’re becoming more common in modern shops, and for good reason: they improve results for you, the customer.

Why It Matters to Your Business

Whether you’re ordering a hundred parts or just a handful of prototypes, here's how working with a fabrication partner who uses welding cobots benefits your timeline, your bottom line, and your peace of mind:

1. Consistent, High-Quality Welds

Cobots follow programmed weld paths with precision—meaning every part is welded the same way, with fewer defects and less need for rework. You get more reliable parts, built to spec every time.

2. Faster Turnaround Times

Because cobots can run longer hours (even lights-out production), they speed up the fabrication process. That means shorter lead times for your projects and less downtime waiting for parts.

3. Cost-Effective for Larger Runs

On higher-volume orders, cobots reduce manual labor costs and improve efficiency—savings that can be passed on to you. It’s a smarter option when consistency and cost control are key.

4. Flexibility for Custom or Short-Run Jobs

Today’s cobots are designed to switch between jobs quickly. If your project includes custom components or small-batch parts, a cobot-equipped shop can still deliver with speed and accuracy.

5. Fewer Delays Due to Labor Shortages

The skilled labor shortage in welding is real—and it can impact timelines. Shops that use cobots are better equipped to maintain production even during staffing gaps, helping your projects stay on schedule.

6. Better Safety = Fewer Disruptions

Cobots can handle hot, repetitive, or awkward welding tasks, helping reduce injuries on the shop floor. That means fewer disruptions, smoother operations, and a healthier workforce supporting your orders.

Bottom Line: Smarter Welding = Better Results for You

When you choose a fabrication partner that uses welding cobots, you're not just getting modern tech—you’re getting:

Faster delivery

More consistent parts

Better value for your budget

It’s not about replacing welders—it’s about combining human skill with robotic precision to deliver better results to your business.

Ready to Work with a Cobot-Capable Fabrication Shop?

At Hawley Services Inc, we use the latest welding cobot technology to provide reliable, high-quality results—whether you need custom brackets or full-scale assemblies.

Let’s talk about how we can bring speed, consistency, and craftsmanship to your next project.

Call us at (616) 322-0209 or email at office@hawleyservices.com to get started.

Great info, team.